SUSTAINABILITY ![]() Construction methods

Construction methods

Surface disposal of tailings involves the use of various dam and embankment structures to create reservoirs that hold both the tailings and plant effluent.

The choice of embankment style may include water retention structures constructed in a single stage or raised embankments, such as upstream, downstream, or centerline varieties.

The determination of the embankment style, influenced by the disposal method and water management needs, takes into account several critical factors:

The selection of the embankment style must align with the constraints imposed by these factors. Additionally, the choice of embankment type is closely linked to considerations related to site location and layout.

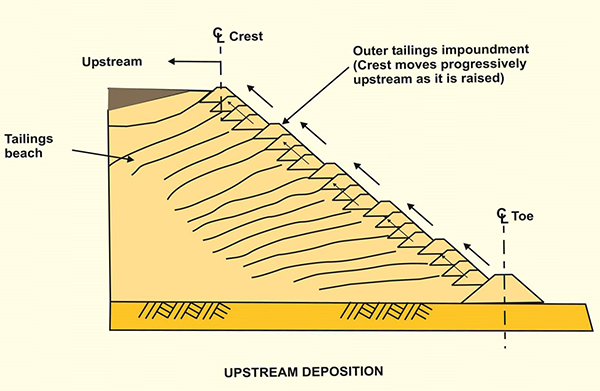

Commencing the process of upstream wall raising involves the construction of a foundational starter embankment at the downstream base (see Figures 1a and 1b). Subsequently, the tailings are discharged outward from the top of this initial embankment, either through spigots or hydro-cyclones. This deposition method creates an extensive beach area composed of coarser materials. In this context, "beach" denotes the surface slope of the tailings formed by water discharge. This beach then serves as the base for the subsequent embankment raise. In some instances, mechanical means are employed for embankment placement, with discharge primarily utilized to build the beach.

For these embankment raises, borrow fill may be used, or beach sand tailings can be excavated from the beach and placed using excavators or front-end loaders. Regardless of the method chosen, some level of mechanical compaction is typically performed on the embankment raise before proceeding to the next stage of dam construction.

The crucial requirement for employing the upstream raised construction method is that the tailings beach must offer a stable foundation for supporting the following embankment raise. Apart from tailings gradation, several other factors can influence the feasibility of this approach. These factors encompass control over the phreatic surface, the capacity for water storage, susceptibility to seismic liquefaction, and the rate at which the dam is raised.

Figure 1a

Figure 1b

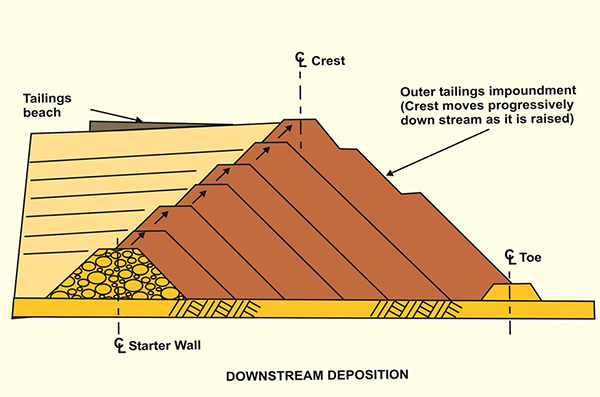

The design specifications for the downstream construction approach share similarities with those used for conventional water storage dams. In the downstream method, like the upstream counterpart, construction begins with a foundational embankment made from compacted borrow materials. However, this initial embankment may consist of either porous sands and gravels or predominantly silts and clays to minimize seepage through the dam. When low-permeability materials are employed in the initial embankment, the design should incorporate internal drains.

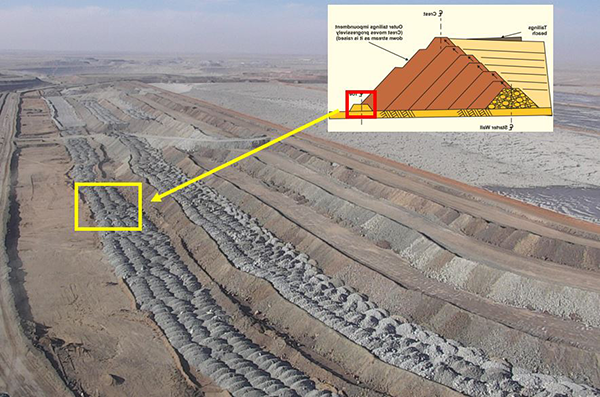

The downstream method derives its name from the fact that subsequent embankment stages are built atop the downstream slope of the previous sections, gradually shifting the embankment crest's centerline downstream as the dam stages are raised (refer to Figures 2a and 2b). Various techniques can be used to deposit tailings in conjunction with the downstream construction method, but peripheral spigotting of tailings is quite common. Therefore, if coarse rock (run-of-mine waste) is used, it necessitates the use of a filter or impermeable upstream membrane on the upstream slope to prevent the tailings from passing through the rock.

The downstream construction method enables the incorporation of drains and impermeable cores to manage the phreatic surface. This approach offers a level of stability not typically found in upstream construction due to the ease of compaction, the integration of phreatic surface control measures, and the independence of dam raises from the tailings deposits for foundation strength. However, downstream raising methods require meticulous planning. Since the base of the dam extends outward as its height increases, careful consideration must be given during the initial embankment layout to prevent encroachment on property lines and topographical limitations. Often, these constraints at the base determine the ultimate height of the embankment.

One significant drawback of this approach is the substantial volume of fill material required to raise the dam. Consequently, thorough planning is essential to ensure that the production rates of fill materials will suffice throughout the embankment's life. Additionally, embankments constructed with downstream raises occupy a relatively large area, which can be disadvantageous when space is limited.

Figure 2a

Figure 2b

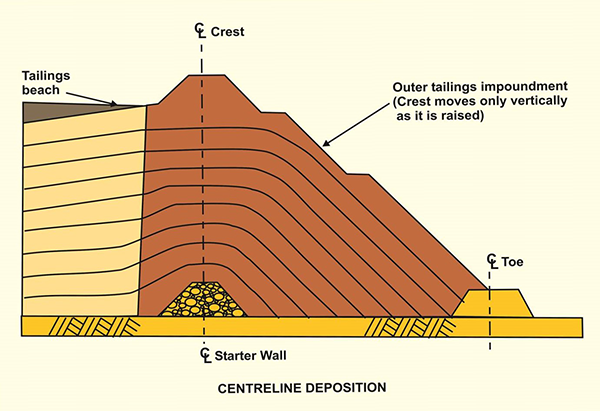

The centreline raising method is a compromise between the upstream and downstream methods; it shares both methods' advantages to a degree while mitigating their disadvantages.- Similarly to the upstream method, a starter embankment is constructed, and tailings are discharged peripherally from the embankment to form the beach. Subsequent raises are constructed by placing fill onto the beach and onto the previous raise's downstream slope.- The raises' centreline is coincident as the embankment progresses upward (Figures 3a and 3b).

The centreline method generally has good seismic resistance.

Figure 3a

Figure 3b

Open-pit mining creates empty spaces, and it might appear that the most environmentally responsible approach to store tailings is within these voids, which originally produced the waste material. However, placing tailings in fully excavated open pits could potentially render those resources unusable. Additionally, a single open pit may not be available for tailings disposal while active mining operations are ongoing. Furthermore, in-pit disposal usually lacks containment walls or has minimal ones, depending on the terrain (refer to Figure 4).

Tailings can be introduced into completed open pits in the form of a slurry, with thickening or filtration, or in combination with waste rock (see Figure 5).

Figure 4

Figure 5