SUSTAINABILITY ![]() Tailing and waste management

Tailing and waste management

By the end of 2021, our 11 operations, including our three JV sites (Asanko in Ghana, Gruyere in Australia, and Far Southeast in the Philippines), had a total of 37 TSFs. Among these, 13 were active, and one was under construction. Of the active TSFs, we had two in-pit TSFs (Agnew and St Ives), six downstream/centre-line TSFs, and five upstream TSFs. As part of our ESG commitments, we aim to reduce the number of upstream-raised TSFs from five to three by 2030.

Our Australian and South African mines are located in relatively arid regions with minimal supernatant water storage. In contrast, our TSFs in Ghana are designed to handle exceptionally high seasonal rainfall. We've implemented stringent controls and performance objectives to ensure the stability of TSF embankments throughout wet and dry seasons. Independent review boards have been appointed at Tarkwa and Cerro Corona. Our technical teams are working closely with Galiano Gold, which manages Asanko, to maintain the operational performance of the lined and downstream-raised TSF. The Salares Norte TSF, a filtered dry-stack dam, is scheduled to be commissioned in H1 2023.

In the Philippines, the FSE TSF is well-managed and shows no signs of instability. Additionally, the facility has freeboard capacity to handle up to a 1:500 year flood event. However, the TSF is situated in an area prone to high seismic activity and frequent typhoons. To better understand the current risk profile and potential risk control measures for the facility, Golden Mine Projects and Lepanto Consolidated Mining engaged external consultants. These studies have been completed, resulting in an independent summary report that encapsulates the study findings.

Following the Brumadinho tailings disaster in January 2019, ICMM members, the UN Environment Programme, and the UN Principles for Responsible Investment formed an independent panel of experts to create an international standard for TSFs. The result was the GISTM, launched on August 5, 2020, as the world's first global standard on tailings management, applicable to existing and future TSFs. The GISTM enhances current mining industry practices by incorporating social, environmental, local economic, and technical considerations. It covers the entire TSF lifecycle, from project inception to post-closure.

Golden Mine Projects, along with other ICMM members, has committed that all TSFs categorized as "extreme" or "very high" in terms of consequences will comply with the GISTM by August 2023. For all other operational tailings facilities not in a state of safe closure, compliance with the GISTM is targeted for August 2025. Shortly after the standard's launch, we initiated a detailed site-specific gap analysis of each Golden Mine Projects-managed TSF to identify deficiencies and establish our compliance plan. This analysis is complete, and we are in the process of addressing all identified gaps. Additionally, we have appointed new Golden Mine Projects' roles specific to GISTM, including Accountable Executives (AEs) and Responsible Tailings Facility Engineers (RTFEs).

Internal self-assessments aligned with ICMM Conformance Protocols are planned for H1 2022 at our two priority sites (Tarkwa and Cerro Corona) and will involve the relevant TSF Engineers of Record (EoRs). Furthermore, we are considering external verification of conformance before the ICMM deadlines, set for Q1 2023.

Every three years, all of Golden Mine Projects' active TSFs undergo an independent external audit. In addition, comprehensive third-party reviews covering operational, legal aspects, and sustainable development are conducted at three-year intervals. The next round of audits is scheduled for Q1 2023. This review process also verifies ongoing compliance with the Group TSF Management Guideline and relevant design guidelines.

TSFs with an "extreme" consequence category rating must undergo this third-party operational review annually. Golden Mine Projects is in the process of transitioning its TSF Management Guideline into a standard that incorporates GISTM requirements and incorporates lessons learned from various TSF-related incidents in recent years. This draft standard has also been benchmarked against guidelines and standards developed by industry peers.

For all our active Golden Mine Projects-managed sites, we retain an Engineer of Record (EoR). This role is fulfilled by a qualified external engineer, supported by their consulting engineering firm. EoRs are responsible for reviewing and approving engineering and design data, operating and monitoring procedures, as-built drawings, and facility inspections to confirm physical integrity, safety, and the performance of ancillary structures.

The Golden Mine Projects Board maintains a high level of oversight over the Group's TSFs through quarterly TSF management board reporting, real-time environmental and geotechnical monitoring instruments, and increased external and independent monitoring verification. We are also implementing initiatives to enhance TSF operational safety, including exploring filtered and dry-stacked tailings (currently being installed at Salares Norte), co-disposal, improved water management, and in-pit tailings disposal where feasible. These initiatives are part of the ICMM's efforts to enhance critical TSF controls and reduce tailings water content.

Golden Mine Projects has progressively introduced several technical enhancements at its TSFs, including:

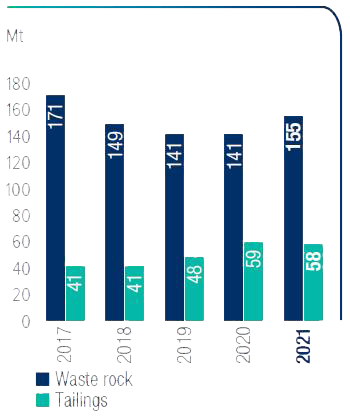

Process plant tailings waste and waste rock, or mineralized waste, are significant by-products of mining operations. Responsible management of these waste streams helps minimize their environmental impact and their impact on our host communities.

Regarding general waste, we have set an internal target to limit the generation of general or non-hazardous waste for disposal in landfills to 2015 levels, which amounted to 11.2kt. In 2021, we generated 1.2kt of hazardous waste and 10.2kt of non-hazardous waste for disposal, successfully meeting our annual target. Golden Mine Projects recycled 63% of all non-mineralized waste generated in 2021, an improvement from 60% in 2020. Specific waste types, such as plastics, scrap metals, oils, and hydrocarbons, are recycled off-site by specialized recyclers.

Tailings dam at our Damang mine, Ghana