SUPPLIERS ![]() Supplier classification

Supplier classification

Golden Mine Projects categorizes its suppliers based on factors such as the impact they have on operations, their cost, and how easily their service or product can be replaced by another vendor. This system helps the company to better comprehend and handle potential risks in its supply chain. It also pinpoints areas where the company relies heavily on specific suppliers for the smooth running of its operations.

Primary suppliers, known as Tier 1, directly provide goods or services—including intellectual properties and patents—to Golden Mine Projects. They form the active supplier base for the company and are evaluated on several performance metrics like on-time delivery, service quality, and invoicing accuracy.

Moreover, these primary suppliers are consistently vetted using a third-party tool to check for any recorded violations and negative media coverage. They are assessed against standards such as labor conditions, environmental concerns, managerial practices, and more.

Key suppliers have a notable influence on Golden Mine Projects’ operations, often having a large presence across multiple operational facets, from personnel to equipment. This makes replacing them quite challenging without an in-depth strategy and substantial transition efforts.

Examples of these significant Tier 1 suppliers are:

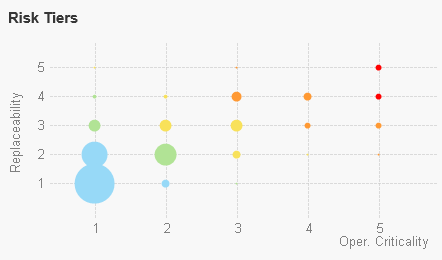

The following gives a glimpse of how Golden Mine Projects determines the importance of a supplier:

The preliminary assessment relies on two factors, each rated on a scale of 1 to 5:

| Criteria / Score | 1 | 2 | 3 | 4 | 5 |

| Operational Criticality | No impact on production | Production inconvenienced | Some production activity is delayed - mine still operational | Production ceases for a short period (days) | Production ceases for a medium period (weeks) |

| Replaceability of the Solution | Quickly replaceable | Quickly replaceable with some effort or loss of quality | Replaceable in short lead-time and with considerable effort | Replaceable with long lead-time and high effort | Irreplaceable in the medium term |

The Supplier Criticality Score is obtained by multiplying these ratings together.

For clarification: A supplier receiving a '4' or '5' in any of the categories is termed as a 'Critical Supplier'.

The last element that helps categorize a supplier as 'Critical' is the annual spend with them.

For instance, in Australia, a supplier with an annual expenditure surpassing A$250,000 p.a. is deemed critical.

Critical Non-Tier 1 Suppliers are suppliers who provide products and/or services to the provider at the next level above in the supply chain (e.g. Tier 1 Suppliers). A critical non-tier 1 supplier is a Malaysian quicklime company who delivers goods to an Australian importer and distributor of quicklime, who then serves Golden Mine Projects' Australian operations.

Tier 2 & 3 Suppliers cater to suppliers directly above them in the hierarchy. For instance, Tier 3 suppliers serve Tier 2, and in turn, Tier 2 cater to Tier 1. Monitoring these suppliers becomes progressively challenging due to the decreasing clarity in their operations as we move down the supply chain.

Golden Mine Projects tries to enhance transparency of these Tier 2 & 3 suppliers by motivating Tier 1 Suppliers to engage suppliers that are locally-owned and run. This approach aligns with Golden Mine Projects' 'Stakeholder' Strategic Pillar, emphasizing the importance of bolstering local procurement and employment. This local engagement is pivotal for Golden Mine Projects' operational legitimacy.